Overview

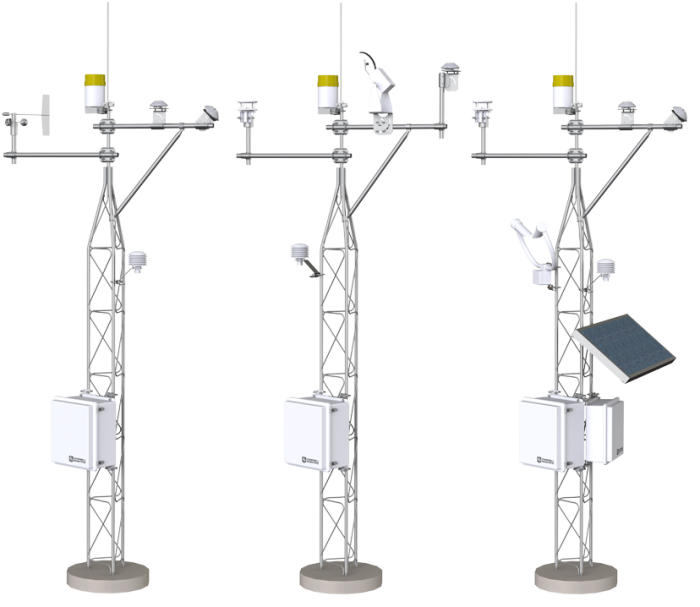

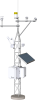

The Solar1000 is an automated data-acquisition system specifically designed for solar monitoring applications. The standard package is designed to meet CaISO standards with AESO variants available. Systems are easily customized with accessories for every aspect of the station, from communications to mounting options.

Typical applications include pre-construction phase solar resource assessment, baseline data collection, and performance monitoring. The Solar1000 simplifies the process of collecting system data by acting as the single point data gateway for environmental, inverter, and meter data.

Measurements

Most of the systems we sell are customized. These systems, however, typically measure the following parameters:

- Air temperature

- Solar radiation - global horizontal (GH)

- Solar radiation - plane of array (POA)

- Surface temperature - back of panel

- Wind direction

- Wind speed

- Precipitation

- Barometric pressure

Benefits and Features

- Contains a Campbell Scientific CR1000 Measurement and Control Datalogger

- Makes thermopile-style irradiance measurements

- Makes thermocouple back of module temperature measurements

- Includes sealed circular connectors on the outside of the enclosure, simplifying sensor hookup

- Reduces installation time by using a prewired/preprogrammed integrated design

- Supports Dynamic Host Configuration Protocol (DHCP) and static IP configuration

- Provides a battery back system that allows data collection during power outages and network failure

- Acts as single point data gateway for environmental, inverter, and meter data

- Modular design promotes customization

- Modbus, CanBus, and DNP 3.0 compliance simplifies integration

Images

FAQs for

Number of FAQs related to Solar1000: 8

Expand AllCollapse All

-

The solar sensors should be cleaned daily—at the minimum, weekly. The required maintenance cycle varies based on location, precipitation, and biologic activity. Desiccant should be changed on a regular interval, but that interval depends on ambient environmental conditions.

-

Yes. The Solar1000 has been designed to meet California ISO specifications.

-

The Solar1000 is both a station for resource assessment and power performance for photovoltaic power production facilities. For example, this system may be used to quantify the potential power that could be generated at a proposed site. During and after construction at a site, the station can be used to provide data that isolates system inefficiencies and provides crucial information to funding agencies.

-

Unless the panels are tracking either in one axis or two, it is not likely that a tracker and pyrheliometer are needed.

-

The CR1000 datalogger has built-in capabilities to be fully compatible with Modbus, as well as DNP3. The intention is to add additional compatible protocols as the industry and markets change and evolve.

-

No. The main concern when installing the system is to ensure that the stand is secure to the ground and that the sensors are aligned and leveled. With patience, these tasks can be performed fairly easily.

-

Depending on the tracker being used, a Campbell Scientific data logger can request data, relay diagnostic information, and potentially control the tracker.

-

No. Sensors are manufactured by Hukseflux, EKO Instruments, Kipp & Zonen, and Eppley Laboratory. Contact Campbell Scientific for more information, including sensor tracker compatibility.