Campbell components mount easily and securely

Overview

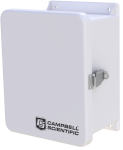

The ENC12/14 is a medium-sized, weather-resistant enclosure that is 12 inches wide and 14 inches tall. It is our most popular enclosure that balances cost with space requirements. This enclosure can house a datalogger, a power supply, and one or more peripherals, depending on the footprint.

Read MoreBenefits and Features

- Weather resistant to protect instruments

- Backplate designed so that Campbell Scientific components mount easily and securely

- White, UV-stabilized enclosure reflects solar radiation—reducing temperature gradients inside the enclosure without requiring a separate radiation shield

Images

3D/CAD Files:

Technical Description

The ENC12/14's backplate is prepunched with one-inch-on-center holes suitable for attaching a datalogger, power supply, and a communications or measurement and control peripheral.

Specifications

| Color | White (Reflects solar radiation, reducing temperature gradients inside the enclosure without using a separate radiation shield.) |

| Construction | Fiberglass-reinforced polyester enclosure with door gasket, external grounding lug, stainless-steel hinge, and lockable hasps |

| Enclosure Classification | NEMA 4X (before being modified for cable entry, conduit, or ground lug) |

| Number of Cable-Entry Seals | 2 medium, 4 small |

| Dimensions |

|

| Weight | 5 kg (11.2 lb) |

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Resources and Links

Product Brochures

Technical Papers

FAQs for

Number of FAQs related to ENC12/14: 15

Expand AllCollapse All

-

The ENC12/14 weighs 11.2 lb. Its internal dimensions are 12 x 14 x 5.5 in.

-

Is a fiberglass enclosure suitable for an installation in a very cold location monitoring corrosion?Our fiberglass enclosures can withstand very cold locations, and their fiberglass/plastic construction is very resistant to corrosion.

-

The terminals do not need to be replaced. Just sand or file the corrosion away, exposing clean copper, and the fittings will continue to be functional.

-

It depends on the device. Most devices have built-in mounting flanges, but some items require a separate mounting bracket.

-

-

Yes. Each enclosure Campbell Scientific sells has a powder-coated backplate with holes on 1 in. centers that match the mounting flanges on our equipment for easy mounting.

-

Backplates are available in sizes designed to fit in Campbell Scientific enclosures: 10 x 12 in., 12 x 14 in., 14 x 16 in., and 16 x 18 in.

-

There is not an easy way to calculate how much desiccant is needed in an enclosure or how quickly the desiccant will need to be replaced. The following conditions affect the replacement interval:

- How much humidity the enclosure is exposed to

- The size of the enclosure

- How often the enclosure door is opened and how long the door remains open

- How airtight the enclosure is

It may be advantageous to use more than one desiccant packet at a time inside an enclosure. Campbell Scientific recommends keeping an extra supply of desiccant on hand for as-needed replacement in the enclosure.

-

The following information is applicable to many of Campbell Scientific’s standard enclosures and prewired enclosures.

Note: The procedure below will not work for torn or damaged seals.

To make a field repair to a loose gasket on an enclosure, first acquire an adhesive, such as standard Gorilla Glue, that is rated for use with polyurethane foam. The adhesive should be compatible with, and recommended for, use with polyurethane foam. Follow these steps:

- Pull the gasket away from the gasket channel, being careful not to tear the gasket. The gasket does not need to be removed completely. Rather, remove only those areas that have pulled loose on their own. To keep the gasket up out of the way, lay a small object (such as a toothpick, pen, or pencil) horizontally across the channel.

- Using an adhesive that is rated for use with polyurethane foam, apply a small bead of adhesive to the gasket channel. Because the adhesive’s only function is to keep the gasket in place, use it sparingly.

- Remove any objects that were holding the gasket out of the way.

- Carefully place the gasket in the gasket channel.

- Wait 1 to 3 hours for the adhesive to cure before closing the door.

Case Studies

Dans le cadre du volet « Prévention des crises et renforcement de la RÉSILIENCE »......read more

The city of Frisco, Texas, sits in an area that experienced severe drought from about......read more

The city of Frisco, Texas, sits in an area that experienced severe drought from about......read more

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences