How We Can Help You

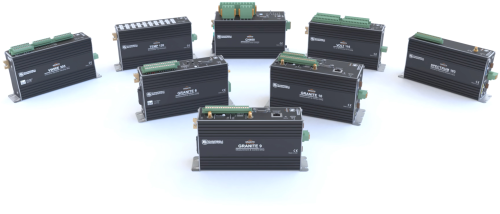

Campbell Scientific’s vehicle data acquisition (DAQ) systems have a proven history of operating at the edge of performance in the vehicle testing environment. This includes extreme and repetitive temperature testing cycles, remote over-the-road testing, and environmental fatigue testing. Systems typically measure temperature, pressure, loads, and strains; and they monitor the vehicle data bus with general-purpose Controller Area Network (CAN) channels. Our systems are rugged, versatile, portable, and reliable. They are compatible with a wide variety of sensors with multiple wireless and wired communication capabilities including cellular, Bluetooth, Wi-Fi, and Ethernet.

A distributed DAQ for vehicle testing lowers the total cost of instrumentation with shorter sensor cable lengths, reduced cable costs, fewer vehicle modifications, and decreased sensor installation time—all with less cable to route. This unique design also improves measurement fidelity with reduced signal interference because components are located closer to the point of measurement.

Watch the GRANITE™ | Vehicle Testing video and the GRANITE™ Series Data Acquisition video.

Learn about our patented VSPECT® spectral-analysis technology at our VSPECT® Essentials web resource.

The dynamic vibrating-wire measurement technique is protected under U.S. Patent No. 8,671,758, and the vibrating-wire spectral-analysis technology (VSPECT®) is protected under U.S. Patent No. 7,779,690.

Learn moreCheck out some awesome examples of what our equipment can do in this area

Customize a System

In addition to our standard systems available, many of the systems we provide are customized. Tell us what you need, and we’ll help you configure a system that meets your exact needs.

Related Product Categories

More Details about Our Vehicle Testing Systems

Data Acquisition for Vehicle Testing

The GRANITE™10 Data-Acquisition System was designed with vehicle testing in mind. As Campbell Scientific’s most computationally powerful data-acquisition system, the GRANITE™10 is the core of the vehicle testing data-acquisition network. Providing four general-purpose CAN channels, the GRANITE™10 is CAN bus and CAN FD compatible. When integrated with the GRANITE™ measurement modules, a complete system is capable of measuring temperature, strain, pressure, load, and many other parameters. The GRANITE ™10 DAQ can support multiple measurement rates simultaneously, ranging from every few hours to more than 10,000 measurements per second. Measurement types, processing algorithms, and recording intervals are also programmable. The GRANITE™10 CAN bus allows time-synchronized storage of vehicle computer data with independently measured data from the GRANITE™ DAQ.

On-board instruction sets contain programmed algorithms that process measurements and output results in the desired engineering units. For example, data can be displayed as rainflow or level-crossing histograms. These rainflow and level-crossing algorithms allow processing for extended periods, not just a limited number of cycles. Our instruction sets also allow unattended measurement and control decisions based on time or conditional events.

Modular Design

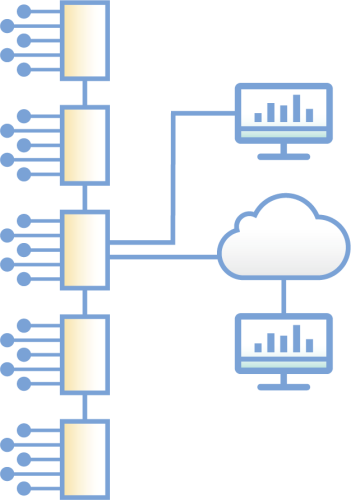

The modular architecture of our GRANITE™ system allows each measurement module to independently connect directly to a PC or DAQ. As an independent module, the real-time measurements can be displayed directly on the PC. One or more measurement modules can be connected to the GRANITE™10 DAQ to create the perfect networked configuration for each application. When connected, they form a time-synchronized, distributed data-acquisition system.

Distributed Networks and Synchronization

Multiple GRANITE™ measurement modules can be distributed throughout the vehicle. Each module is connected to a central GRANITE™10 DAQ. This networking capability decreases the quantity and lengths of the sensor cables between the sensors and the GRANITE™10. Fewer sensor cables reduces cost, improves system simplification, and lessens the risk of signal corruption from noise.

Synchronization is key to the success of a distributed network. There are three significant levels to the GRANITE™DAQ synchronization:

- The GRANITE™10 has a built-in GPS and precision master clock.

- The pulse-per-second signal from the GPS is accurate to 1 µs. If enabled, the GRANITE™10 will phase lock its operating clock to within 200 ns of the GPS clock. So, multiple independent DAQ systems spread over potentially vast geo-spatial regions can be synchronized with a maximum timing error between DAQ systems of 1.2 µs.

- Independent of the GPS, a temperature-compensated, high-precision, on-board, real-time clock will keep its own time with an accuracy of ±3 min/year.

- Within a single DAQ system, comprised of a GRANITE™10 and GRANITE™ measurement modules, the measurements are all synchronized to the master clock of the GRANITE™10 (sourced by either the GPS or precision on-board clock) via the CAN Peripheral Interface (CPI) or Ethernet Peripheral Interface (EPI) measurement buses.

- CPI synchronization between measurement modules in the same DAQ is ±5 µs. The overall physical range of the bus varies up to 2,000 ft depending on the data rate.

- EPI synchronization between measurement modules in the same DAQ is ±50 ns. The physical range of the bus is 300 ft per network connection. Daisy-chained connections can span thousands of feet.

- For extremely time-based-sensitive applications, the GRANITE™ SPECTRUM measurement modules are used with EPI synchronization. Within each module, the analog electrical signal delay is calibrated and compensated to reduce the timing delay mismatch to ±10 ns channel-to-channel.

Sensors for Vehicle Testing

Because each of the GRANITE™10 DAQs are compatible with almost every commercially available sensor, our systems give you the freedom to use the sensors that best meet your application. GRANITE™ measurement module channel types include analog (single-ended and differential), temperature (thermocouple and thermistor), bridge, switched excitation, continuous analog output, anti-aliasing filter, and digital input/output (I/O).

Typical sensors used with our systems include thermocouples, pressure transducers, pulse pickups, flow transducers, potentiometers, strain gauges, load cells, digital switches, accelerometers, Linear Variable Differential Transformers (LVDT), and tilt sensors.

Data Retrieval

Communication interfaces for retrieving, storing, and displaying data include direct connection to a PC or laptop, microSD cards, Ethernet, and several options for wireless communication (including built-in Wi-Fi).

Software

Our PC-based software options support connecting the GRANITE™ measurement modules directly to a PC or scheduling remote, automated data collection from the GRANITE™10. Real-time monitoring and control simplify the entire data-acquisition process, while robust error-checking ensures data integrity. We can even help you post your data to the Internet.

Testing Possibilities

Our data-acquisition systems have been instrumental in testing the following:

Field Testing

- Chassis monitoring

- Road noise

- Vehicle speed

- CAN bus data acquisition

- Environmental conditions

- Performance

- Temperature monitoring

Laboratory Testing

- Extreme temperature environments

- Large channel counts

- Chamber parameters

- Component longevity/durability

- Chassis monitoring

Case Studies

The Space Shuttle Endeavor carried the CR10 and CR9000 dataloggers into orbit as part of......read more

Phil Ayliff Products of Warwickshire, England, is a world leader in the development and manufacture of......read more

Campbell Scientific data-acquisition systems are used extensively for vehicle testing by the UK-based auto manufacturer,......read more

Instrumentation engineers from Daewoo Motors used a Campbell Scientific CR7 Measurement and Control System during......read more

The Aston Martin used a CR7 Measurement and Control System for environmental testing on its......read more

Related Integrators

Articles and Press Releases

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences